When I published this list of New Year’s resolutions earlier this month, there was one I forgot: create a cupping form for farmers.

The SCAA cupping form remains the long-reigning standard. But there has been plenty of talk about alternative cupping forms in recent years, from Shawn Steiman’s call for all-out sensory revolution during the 2011 SCAA Symposium, to this article in Roast Magazine profiling roasters who have made less radical modifications to existing forms for different reasons: to account for differences in post-harvest processes, align the evaluation process more closely with their particular sensory priorities, or just simplify the whole affair. We don’t want to burn anything down, but we do think that incorporating actionable insights into traditional cupping forms could make them more useful for growers.

Cupping forms and tasting notes are market-facing and descriptive. Growers could use a form with notes that are farm-facing and prescriptive.

One that doesn’t just tell them a coffee is good or bad, but also tells them why.

And “so, what”–what farmers can do about it if their coffee doesn’t make the grade.

Ideally, it would also give them an idea of the quality frontier of their farms–the highest scores they can realistically hope to achieve through improvements in practices they can control.

In Colombia we are working with industry allies to create one. We started down this road a few years ago in Central America with our friends from Cooperative Coffees as part of our CAFE Livelihoods project. We sent them samples every year and in return they sent us cupping results using streamlined forms with three columns of feedback: one for scores, another with detailed cupping notes and a third column attributing what they tasted in the cup to specific farm-level practices, with particular focus on defects, year-on-year changes in cup profile and potential for improvement. Here are some excerpts from the third column of a 2011 Nicaragua report, with the parts I consider particularly useful in boldface.

A loss from last year’s score. The cups were very vegetal and phenolic. Flavors potentially point to improper drying.

Greater insect damange and presence of sour beans produced cups that were very unclean and aged tasting. Potentially developed mold from improperly dried coffee? Very dirty compared to last year’s samples.

Nice improvement over last years sample. Grape flavors dominate and make this drink more like a nice red wine than a coffee. Great potential for this coffee.

We are picking up in Colombia where we left off in Nicaragua, trying to be more systematic this time around in targeting the recommendations cuppers make to growers. Counter Culture Coffee, cited in the Roast article for its record of innovation in sensory evaluation, is leading the charge, along with five other U.S. importers and roasters advising our Borderlands Coffee Project.

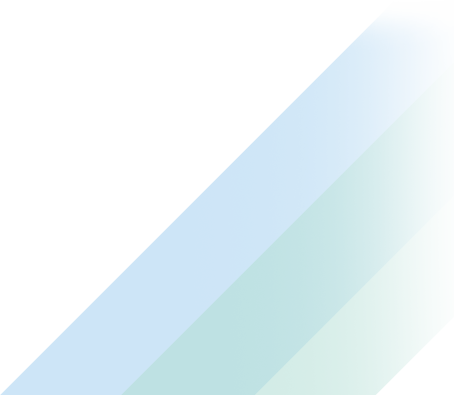

Across the top row of the form pictured above are the traditional SCAA sensory evaluation categories and a place to register each coffee’s overall score.

The innovation starts in the second row, which identifies variables farmers can control on the farm and at the mill, with space for cuppers to scrawl comments related to each–congratulations for good practices that come through in the cup and recommendations that may help the farmer do better next time. Finally, the form is anchored in the lower-right with a space for each coffee’s “potential quality frontier”–the top score a cupper feels a farmer is capable of if he or she were to act on all the enclosed recommendations.

This final box helps roasters identify for special attention growers who have potential for big gains in quality or whose upper bounds reach stratospheric levels. It also helps inform the decision about how a farmer should allocate one of his or her most important resources: time. A grower who may be producing coffees that score 80 points with an upper bound of 82 may decide the additional labor associated with a modest improvement in cup quality may not be worth it. But a grower whose coffee is scoring 84 with a quality frontier closer to 89 may decide to act on the cupper’s recommendations and seek quality premiums.

Four caveats.

First, this is not to suggest that coffee associations don’t need cuppers perform market-facing, descriptive sensory analysis as part of their work to link smallholders to markets. They do, of course. But for the average smallholder grower who will not become a Q-graded cupper, an expanded cupping form that includes actionable information to improve cup quality may be more valuable that one that doesn’t.

Second, this kind of form may have the most value when it is used in the context of a direct relationship with growers–one in which regular visits to farms to see the conditions of production, harvest and processing up close complement far-off cuppings back in the lab.

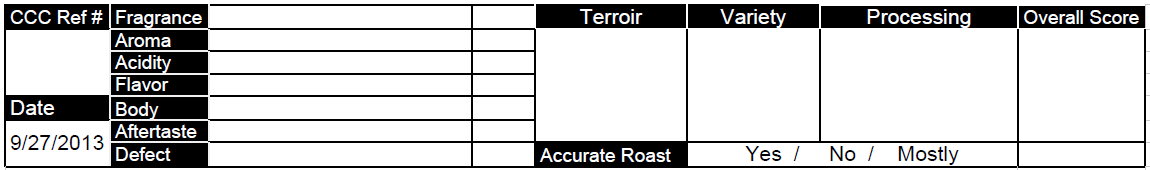

Third, getting this right will take a lot more time and a lot more iterations. It may require new kinds of training for cuppers. And, of course, there is no guarantee of success. The one pictured above is already the fourth iteration of the original draft form pictured below–the “Double Cupping Form” created last September by Counter Culture’s Tim Hill. He used it for three months before scrapping it and starting over.

Fourth and perhaps most important, this whole enterprise assumes that cuppers have a deep understanding of farming and milling processes, the experience needed to attribute cup characteristics to specific farm-level practices, and ultimately the ability to generate appropriate recommendations. It is a big assumption. But until WCR gets its sensory program off the ground, the best thinking about what practices drive coffee quality probably lies dispersed in the minds of coffee buyers who have logged millions of muddy-boot miles in the coffeelands.

Feedback, please!